Flat & Fiber Laser Cutting Capabilities

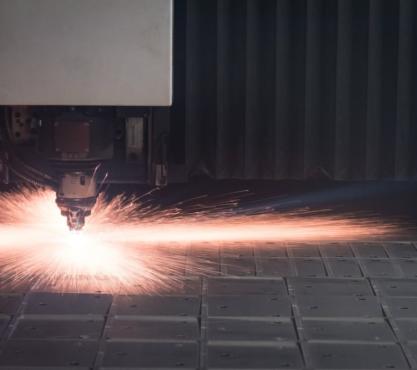

We can produce parts with extremely high edge quality using our vast knowledge base we have amassed since our inception in 1997. Whether you require high-quality paint-ready edges in steel to 3/4 inch thick or thick plate cutting to 2 inch we are your partner. We specialize in high mix/larger volume complex parts.

Call us with your simplest to your most demanding parts as our engineers and operators love a challenge. Do not forget to check out our videos to see our flat laser cutting equipment in action!

Please send us your cad data in *.dxf or *.dwg formats so we can expedite your quotes and orders! Please also include a PDF drawing for other pertinent information.

Laser Cutting Capabilities

- Laser power up to 24,000 watts

- Bed sizes are 60 x 120 and 80 x 160 inches and include over/under pallet changers

- All are automated with load/unload and “PartMasters” that deliver ergonomic operator part unloading to reduce operator fatigue

- Four machines are serviced with two automated material storage and retrieval towers for both raw stock and cut sheets

- Cutting assist gases include nitrogen, oxygen, air, and a specialty blend of nitrogen & oxygen. Delivery pressures exceed 500 psi for the most demanding applications

- Stainless Steel cutting to 1-1/2 inches

- Steel cutting to 2 inches thick

- Aluminum to 1.5 inch thick

- Copper, brass and bronze to 3/8 thick

- Titanium to 5/16 inch thick

- Aerospace alloys to 1 inch thick depending on material composition

- Tolerances to as small as +/-0.002 inches on internal shapes but dependent upon thickness and materials cut. Call to discuss in detail with our application engineers or estimating department

- Edge taper to ½ of 1 degree (dependent upon the thickness and material type, call to discuss)

- All materials can unloaded inside our building to keep your materials clean and corrosion free

- Maximum material lift is 5000 pounds and 5 inches high, blocked or on skids

- Capable of ultra-high-speed cutting utilizing fly cutting technology for round, square, rectangular or other specialty shaped holes and slots (limited to 14 gage and under thicknesses).

Flat Laser Cutting Applications

- Adjustable basketball systems

- Agriculture equipment

- All-terrain vehicles (ATVs)

- Bar fixtures

- Bed frames

- Brush guards

- Bumpers

- Construction equipment

- Display cases

- Engineered architectural structures

- Exercise and Fitness equipment

- Folding tables

- Food and sneeze guards

- Forklift equipment

- Frames

- Garment racking systems

- Hitches

- Industrial tables

- Machine frames

- Medical bed frames

- Medical carts

- Offroad equipment

- Outdoor signs

- Playground equipment

- Point of purchase display

- Racking supports

- Roll bar cages

- Shelving

- Sign stands

- Store fixtures

- Towbars

- Trusses

- Weightlifting wall mounts

- Wheelchair frames